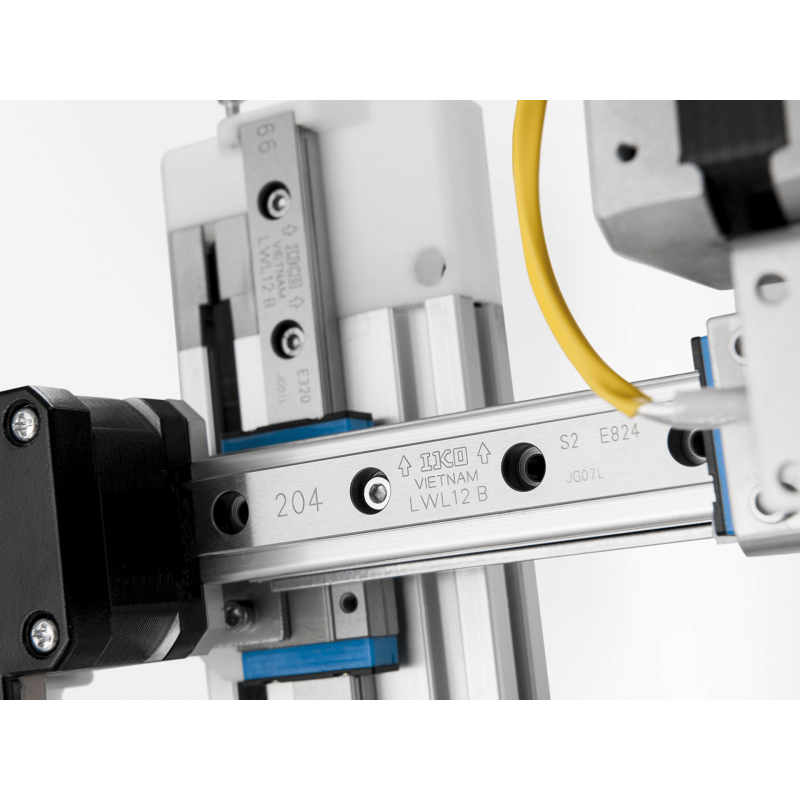

PLA, flexible filament, Woodfill, and more can be printed by Cetus. Most comparable printers are less than or equal to 15cm in size.Ĭapabilities that are versatile, allowing users to be as creative as one wants. Users don’t have to worry about leveling the machine before getting started!Īlthough Cetus has a small footprint, it has a large construction volume. The Y-axis is factory calibrated, so users can start printing. As a result, the construction surface is smooth and parallel throughout the X-axis. There are no moving elements between the slider and the construction plate because it is attached to the linear guide. These rails provide hours of trouble-free, high-precision 3D printing.Ī 3mm aluminum plate also serves as the construction plate guaranteeing that the build surface is flat. The Axis is equipped with high-quality, self-lubricating linear rails. It is made up of six simple to assemble pieces. With high-quality components and a minimalist design, it’s simple to put together. It comes with a spool holder that works well. It will perform as predicted, with no clogging or cracking. Get the hot end temperature heated up, insert the material into the filament tube, and direct it into the extruder top end. The nine-point matrix does an outstanding job of ensuring that the bed is level. The UP Studio software-assisted calibration is well-designed. Tiertime hasn’t skimped on the details, as evidenced by small features like cable mounts linked to the vertical Z axis. The Cetus MK3 3D printer assembly strikes a nice balance between accessibility and a handy kit. Installing the 4 connectors to the components, fixing the X/Z axis rails to the chassis on which the mainboard and Y axis mount reside via a pair of screws, fitting the extruder and fitting the bed plate to the Y-axis are all part of the procedure. Thus, making the Cetus construction quite simple. Tiertime provides instructional videos on their YouTube page. The components are well packaged in a tiny box with interior Styrofoam trays, as expected. Optional hardware upgrades and additional functions are also available.Īlthough the X/Z axis and mainboard/Y-axis rails are constructed, the Cetus ships are dismantled in kit form. Users will be able to make adequate use of this device with some personal changes. If one comes from the industrial field, they could find this one insufficient.

MK3 provides all the capabilities engineers expect from a high-quality 3D printer. The majority of people who opt to invest in this product will be pleased with the outcomes it may provide. Users won’t need an engineering degree to master it effectively. There are others who seek to make a living by manufacturing and selling their own goods at home.įinally, there are the engineers, who have extensive experience with this procedure. Hobbyists like the manufacturing process and what new creations they can make. Various categories of people can benefit from such a product. Source: Cetus 3D Exact Purpose of the Cetus 3D Printer For more sophistication, the MK3 has available modifications that can improve the driving experience. Their Cetus MK3 3D is easy-to-use and technically sound. With a track record to their name, the initiative was embraced by many supporters.Ĭetus provides its consumers with extensive 3D printing capabilities. In 2016, Cetus was crowdfunded by Tiertime. Tiertime, a well-known printer manufacturer. Cetus 3D is the solution to all the printing problems.

0 kommentar(er)

0 kommentar(er)